Design a heat exchange for the duty/ Chemical Engineering

Design a Heat Exchanger for the Following Duty:

Reduced crude oil leaving a distillation unit with a flow rate of 3166.04 kL/d at 268 oC and is to be cooled to 243 oC by exchange with 62.8 kg/s pre-flashed crude oil coming from pre-flash unit at 206 oC. A pressure drop of 0.8 bar is permissible on both streams. Allowance should be made for fouling by including a fouling factor of 0.0003 (W/m2 oC)-1 on the reduced crude stream and 0.0002 (W/m2C)-1on the pre-flashed crude stream. Design and optimize a suitable shell-and-tube heat exchanger that can satisfy the above mentioned duty.

Hints:

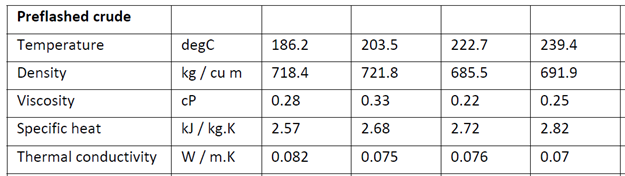

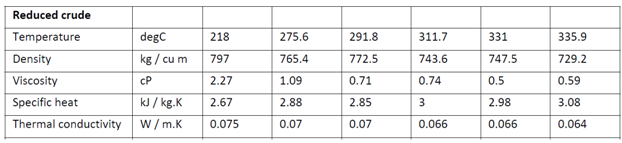

Appendix 1: Physical property data

Note that both pre-flashed crude and reduced crude are completely liquid over the range of temperatures and pressures experienced in the exchangers

Please include a brief comment on economic aspects of heat exchanger design including impact on overall heat transfer coefficient.

Please be sure to state any assumptions made in the calculations with justifiable reasons.