What is the process time of the order picker- Operation Management

1. Metters Cabinets, Inc., needs to choose a production method for its new office shelf. It could implement either a product focus process or repetitive process. To help accomplish this, the firm has gathered the following cost data:

| Process Type | Annual Fixed Cost | Variable Cost (per unit) | |

| Labor | Material | ||

| Product Focus | $50,000 | $10 | $10 |

| Repetitive Focus | $25,000 | $18 | $12 |

Compare these two process types using a crossover chart. Find the production volume that Metters Cabinets is indifferent between the two process strategies.

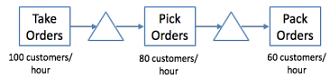

2. Wally’s Widget Warehouse takes orders from 7 AM to 7 PM. The manager wants to analyze the process and has provided the process flow diagram shown below (with capacity rates at each step). There are three steps required to ship a customer order. The first step is to take the order from a customer (one customer places one order). The second step is to pick the order for the customer, and then they have to pack the order ready for shipping. There are currently only three workers taking care of these three steps; one for each.

Wally wants to figure out the following:

a. How many customer orders at most can this process deal with per day assuming a 12-hour working time?

b. What is the process time of the order picker?

c. If orders arrive every 1.5 minutes, what is the process utilization? (Hint: how many orders have arrived in one hour as the input?)

d. Wally is not satisfied with the number you give in (a); he wants the process capacity to become larger. There is a worker recently hired. Who do you want the new worker to help? Order taker, picker, or packer? Why?

e. Following question (d). Assume that the new worker can help double the capacity rate at the step he is sent to. Would hiring this new worker double the number you give in question (a)? Why?

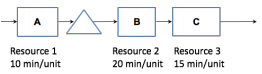

3. Consider the example we did in class:

Suppose that each output unit generates $10. An extra resource (1, 2, or 3) can be leased for $14 per hour. If you have a budget of $28 (that is, you can lease at most two resources), should you go for it? If yes, which one/ones should you lease? And how much is your net hourly gain if you are about to lease?

4. Auto pistons at the South Florida plant are produced in a forging process, and the diameter is a critical factor that must be controlled. From sample sizes of 10 pistons produced each day, the mean and the range of this diameter have been as shown in the spreadsheet.

Hint: you may need Table S6.1 in the textbook.

a. If the population (process) standard deviation is 0.5, what are the Upper Control Limit and Lower Control Limit for sample means using 3-sigma?

b. Without the knowledge of the population standard deviation, find the Upper Control Limit and Lower Control Limit of sample means using 3-sigma.

c. Find the Upper Control Limit and Lower Control Limit for the range using 3-sigma

5. Five data entry operators work at the data processing department of the Georgia Bank. Each day for 30 days, the number of defective records in a sample of 250 records typed by these operators has been noted, as shown in the spreadsheet.

a. Establish the 99.73% upper and lower control limits for a p-chart.

b. When we apply the control limits, what would we do if we saw a day’s sample (250 records) has 21 defective records?